Are you looking to optimize your biomass pelleting process and improve its efficiency? Focusing on the mechanical dewatering phase of pellet production is crucial when aiming to enhance biomass capacity and quality.

The secret to enhanced productivity isn’t about intensifying the drying process but working smarter. The answer lies in heavy-duty high-pressure press technology, which enables you to increase capacity while operating more energy-efficiently.

Still wasting energy on traditional drying?

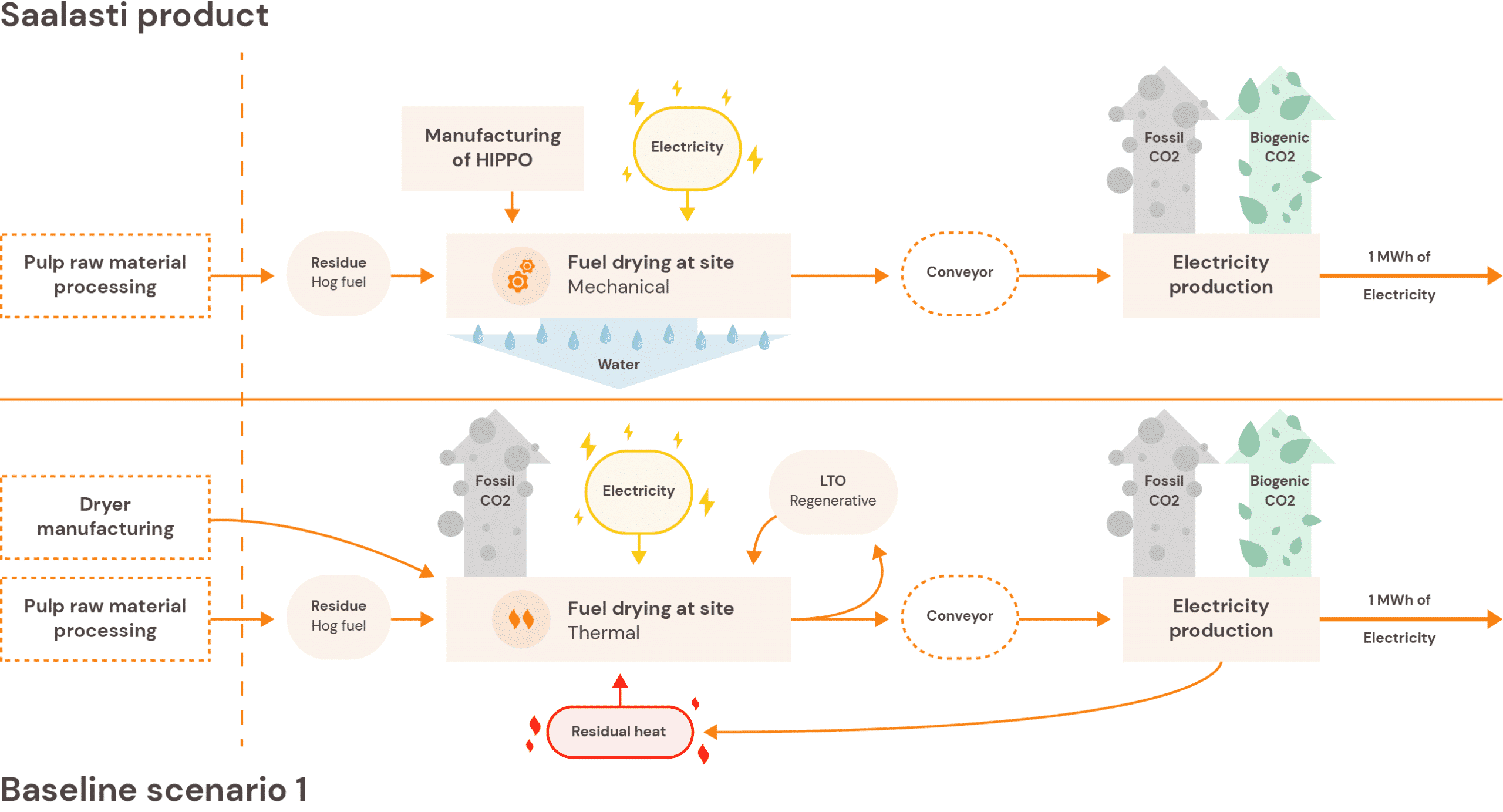

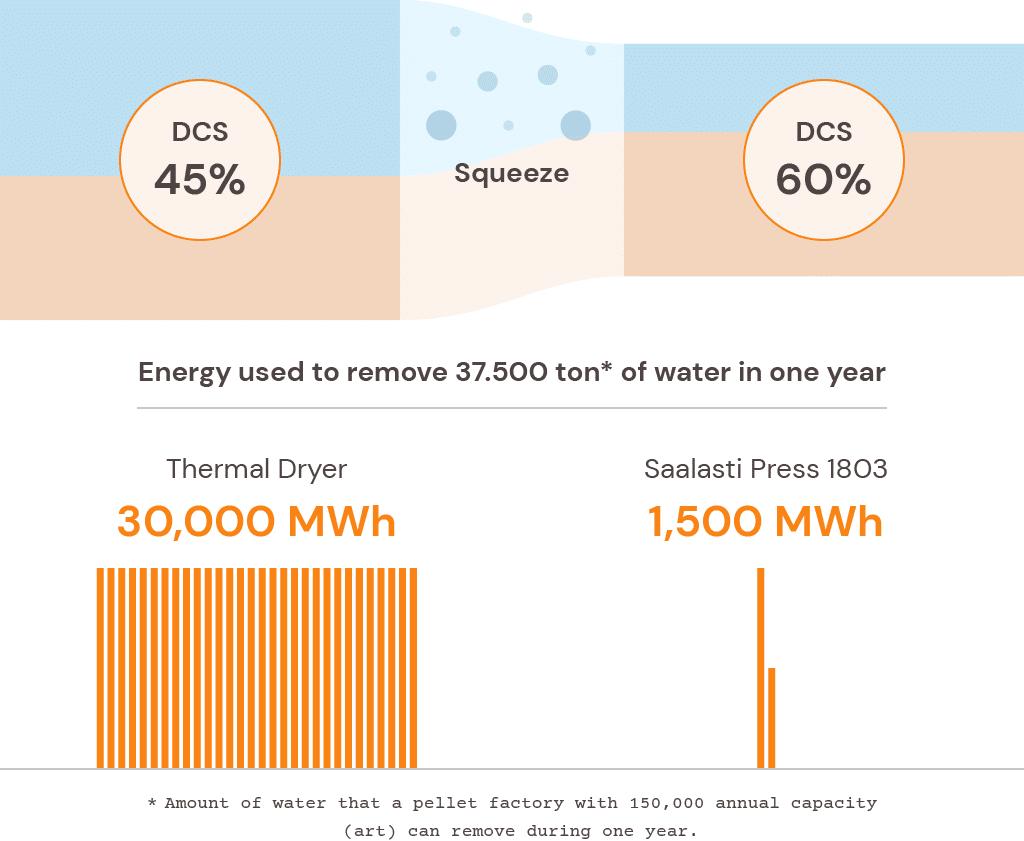

Traditional biomass pelleting processes rely heavily on thermal drying. However, this approach has significant drawbacks: it consumes vast amounts of energy and leaves much to be desired regarding production efficiency and material quality.

What if you could skip most of that energy-intensive process? What if you could utilize mechanical pressing to enhance the entire thermal drying process while optimizing your production flow?

Modern mechanical dewatering technology offers an efficient alternative by removing water before thermal drying, significantly reducing energy requirements. When mechanical dewatering minimizes the load on your thermal dryer, the freed-up drying capacity becomes available for processing additional biomass. This translates into a significant production increase using your existing equipment.

For biomass processors and pellet manufacturers, the benefits are clear and measurable:

- Increased production capacity without investing in a new dryer.

- Higher pellet sales volume and market reach.

- Improved cash flow from additional production.

- Lower investment compared to a new thermal dryer.

The mechanical press offers a cost-effective alternative to investing in additional thermal drying capacity, making it an attractive solution for businesses looking to expand their production.

Our biomass pelleting optimization delivers proven results:

- Up to 50% reduction in energy consumption

- Significant increase in production capacity using existing equipment

- Enhanced product quality through improved process control

- Year-round stable production, regardless of seasonal variations

These benefits can be realized without replacing your existing production lines. The addition of mechanical dewatering technology enhances the efficiency of your current thermal dryers by reducing their workload.

See also: Dewatering press: What are the benefits of mechanical drying?

New generation solution for biomass pelletizing: Hippo Press

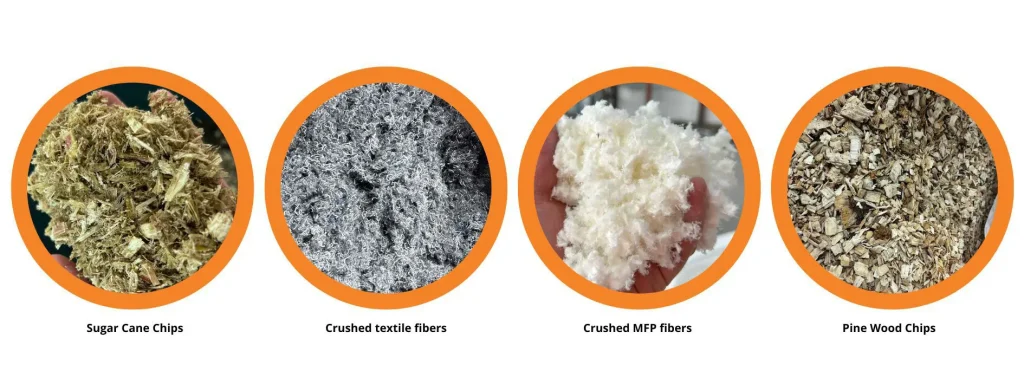

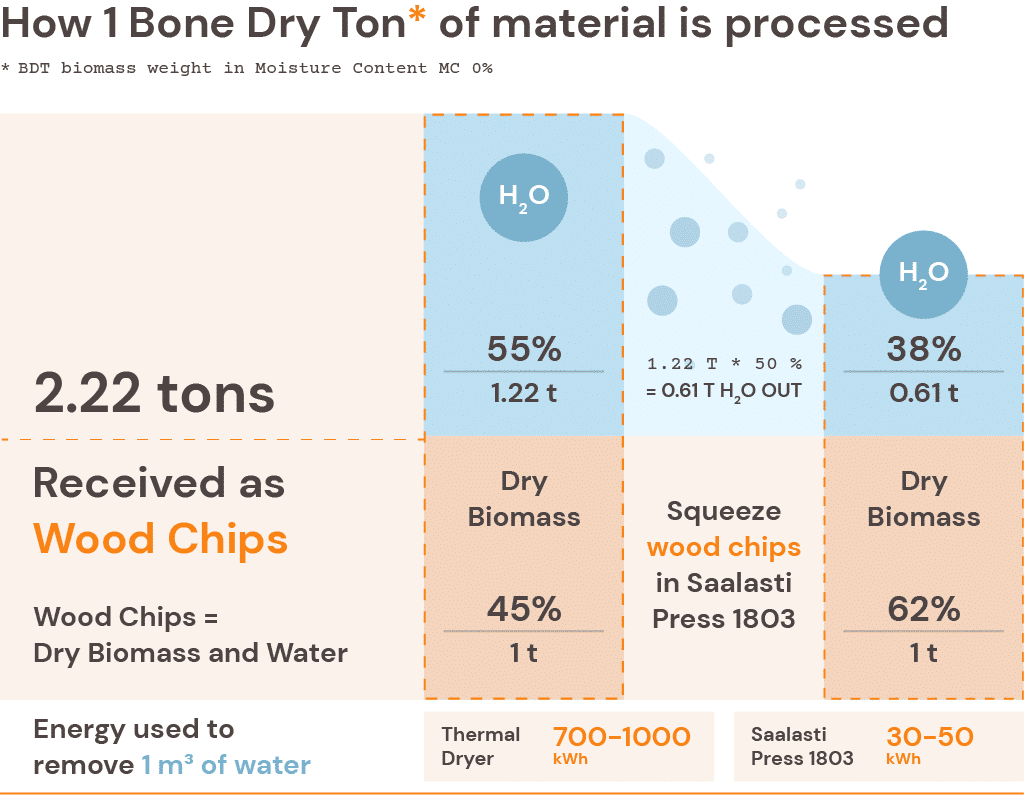

The Saalasti High-Pressure Press revolutionizes biomass pelleting by efficiently reducing moisture content in biomass materials such as wood chips and sawdust.

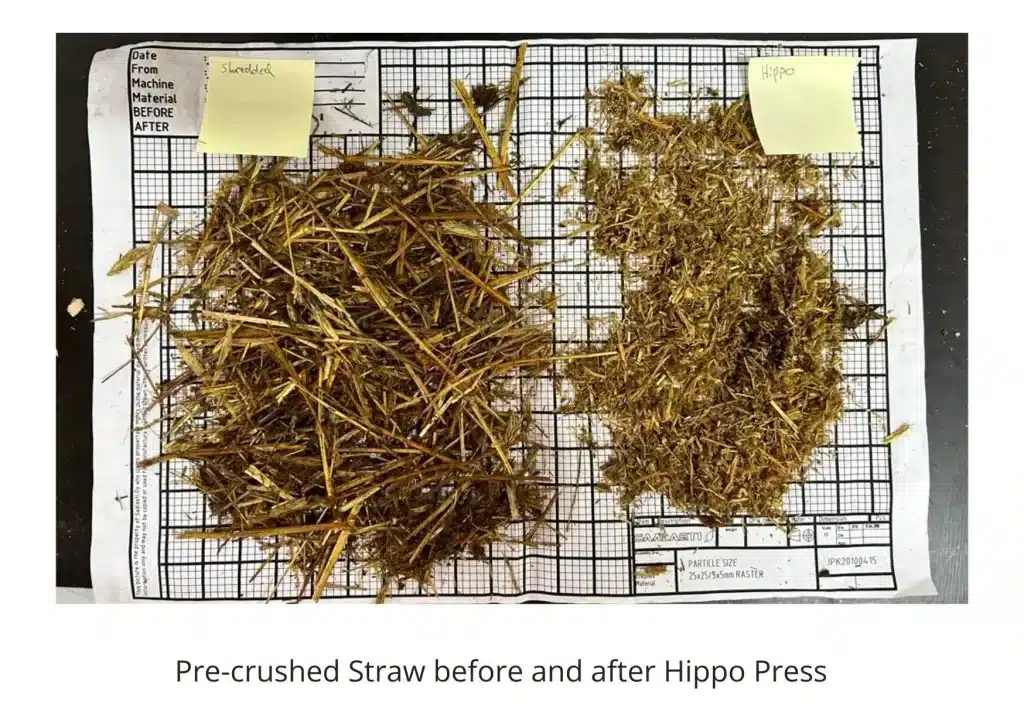

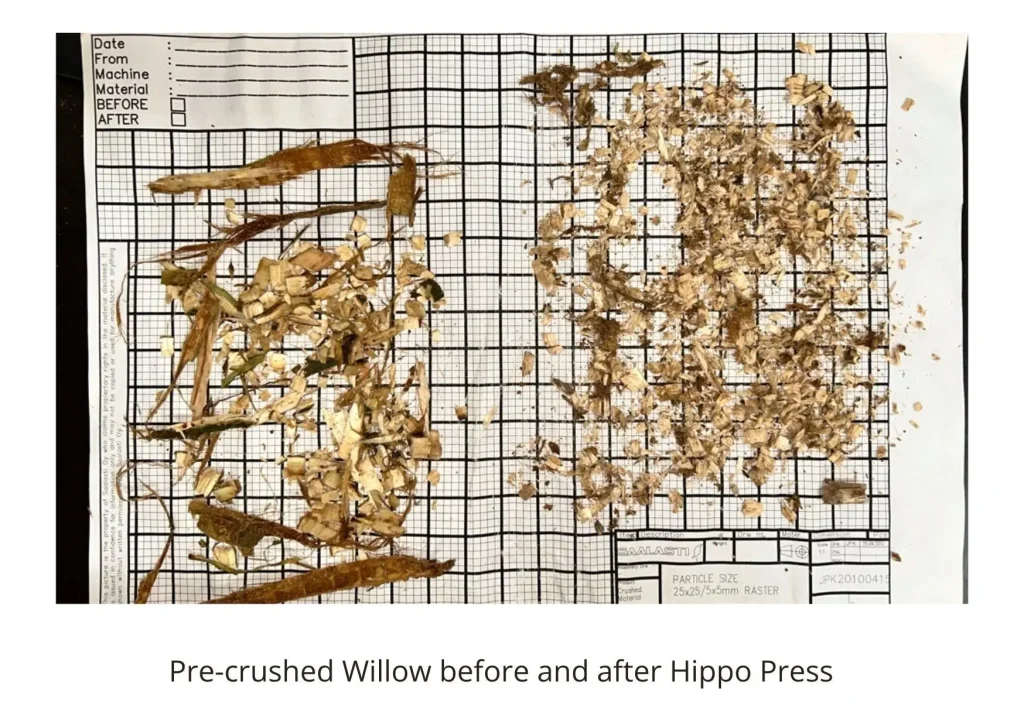

For pellet manufacturers, the benefits reach far beyond simple dewatering. The press’s mechanical action partially crushes the wood chips, increasing the surface area for more efficient thermal drying. This creates consistently higher-quality input material for your pelletizing process.

What matters most for your production is reliability and consistency. The press delivers stable moisture content regardless of seasonal variations in raw material, ensuring your downstream process runs smoothly with minimal interruptions. The pre-crushed material reduces wear on your hammer mills and pellet presses, leading to lower maintenance costs and extended equipment life.

The technology particularly shines in demanding production environments. Its robust design effectively handles feedstock impurities while delivering homogeneous output that optimizes the entire pelleting process. The result is more consistent production rates and higher-quality pellets.

Hippo enables your plant to process more material through your current dryer system, increasing throughput and producing more pellets per time unit.

Biomass pelletizing success story: boosting production without the need to add heat

Van Roje, a German softwood sawmill and pellet manufacturer, needed to double its pellet production from 40,000 to 80-90,000 tonnes annually. However, its existing belt dryer and heating plant faced capacity limitations.

The company implemented Saalasti High-Pressure Dewatering Press 1803 “Hippo” as a solution, removing approximately half of the water from wood chips and sawdust before thermal drying.

With the Hippo press, Van Roje increased their production from 60 to 90 tonnes using the same amount of heat without requiring additional combustion systems or dryer investments.

The solution enabled year-round steady operation, eliminating previous seasonal capacity fluctuations that had reduced winter production by up to 50%.

Calculate your potential?

Our optimization service helps you understand the full potential of your current drying process. We’ll analyze your monthly energy costs and calculate how much mechanical dewatering technology could increase your production capacity.

Our team of experts is ready to analyze your current biomass pelleting process and show you exactly how much you could:

- Increase your production capacity.

- Reduce your energy consumption.

- Improve your bottom line.

Don’t let your competitors get ahead. Contact our biomass pelleting experts today and discover your potential!

Starting the new project: Saalasti’s Project Manager Henri Kuismin, Oulun Energia’s Director of Fuel Sourcing Lauri Heilala and Project Engineer Samuli Korpela. Photo by Oulun Energia.

Starting the new project: Saalasti’s Project Manager Henri Kuismin, Oulun Energia’s Director of Fuel Sourcing Lauri Heilala and Project Engineer Samuli Korpela. Photo by Oulun Energia.

¢

¢