Bark Press - Saalasti Bark Press SP 1620

The most popular Bark Press on the market, trusted by valued companies worldwide. With maximal water removal ability, massive capacity and the longest expertise.

The most popular Bark Press on the market, trusted by valued companies worldwide. With maximal water removal ability, massive capacity and the longest expertise.

The Saalasti Bark Press is a market-leading mechanical dewatering specialized press used by the world’s most respected pulp mills and fiber-based biomass processing plants.

The solution stands out for several reasons:

It’s important to note that the Saalasti Bark Press ensures continuous high-performance and stable operation throughout the process, and we do not only promise maximum water drainage percentage for a certain amount of material at a specific stage of the process. The benefit to you is that your process runs as efficiently as possible from season to season!

When you are looking for a best-performing solution to bark handling and removing the moisture of the fiber-based biomass, Saalasti Bark Press offers both reliable, economical and long-lasting value.

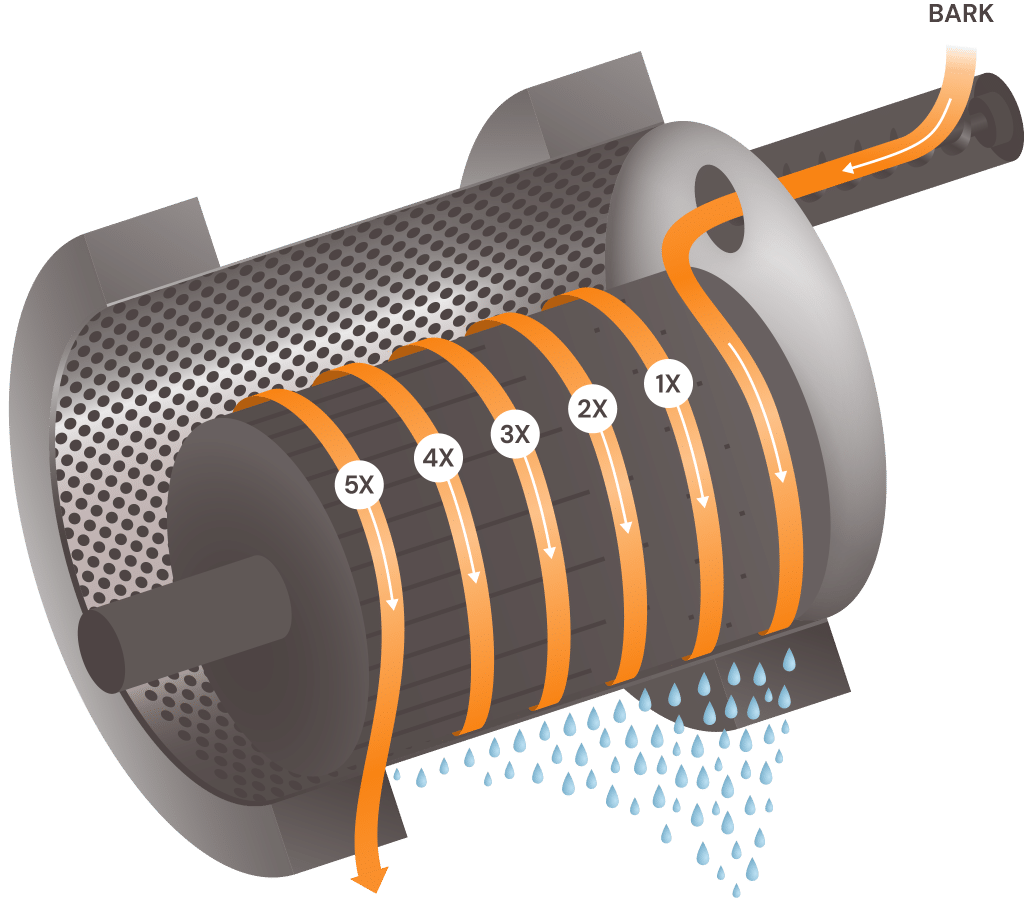

The technology of the Saalasti Bark Press guarantees maximum water drainage capacity for fiber-based biomasses. The operation of the Saalasti bark press is based on mechanical dewatering, which efficiently and economically removes excess water.

What makes it special:

Saalasti Press is ideal for handling bark for a wide range of wood species, including coniferous species as well as more difficult materials such as eucalyptus.

The Saalasti Press bark press is especially popular for bark dewatering in pulp mills and other fiber-based biomass plants where high capacity is required. We continue to conduct state-of-the-research on a wide range of materials to determine the suitability of other fiber-based biomasses. These include elephant grass, cellulosic fibers, sugar cane bagasse etc.

If you want to know whether the Saalasti Press is suitable for your facility’s material, please get in touch, and let’s put it to the practical test. We can assess the material’s compatibility at our test laboratory before deciding to acquire the machine.

We offer turnkey deliveries, equipment upgrades, comprehensive maintenance services, and OEM spare parts. We continuously supply the most common spare parts to deliver new parts as quickly as possible.

| Saalasti Press 1615 M | Saalasti Press 1620 M | Saalasti Press 1620 L | |

|---|---|---|---|

| Capacity* | 80 loose m3/h | 100 loose m3/h | 120 loose m3/h |

| Materials | eucalyptus and other biomasses that are drier than average | coniferous and deciduous bark, other biomasses that have a higher water concentration than average | coniferous and deciduous bark, other biomasses that have a higher water concentration than average |

* Processing capacity is indicative only. The exact capacity will be determined with our experts.

FAQ

Let’s find out! We can test the suitability of your material on our test laboratory equipment. Bark Press is suitable for many fiber-based biomasses, including those not mentioned on this page.

We are doing brief testing starting from the laboratory to define the most suitable process for purposes with the highest efficiency and output of material.

The automation of Saalasti’s machinery ensures independent operation around the clock, every day of the year.

For more information about the Saalasti Press bark press, download our product brochure here, or contact us using the contact form here.

Want to know more about the Saalasti Press bark press and our other machines? Fill out the form below and we’ll get back to you within two business days.

"*" indicates required fields