Squeeze more profit from wood

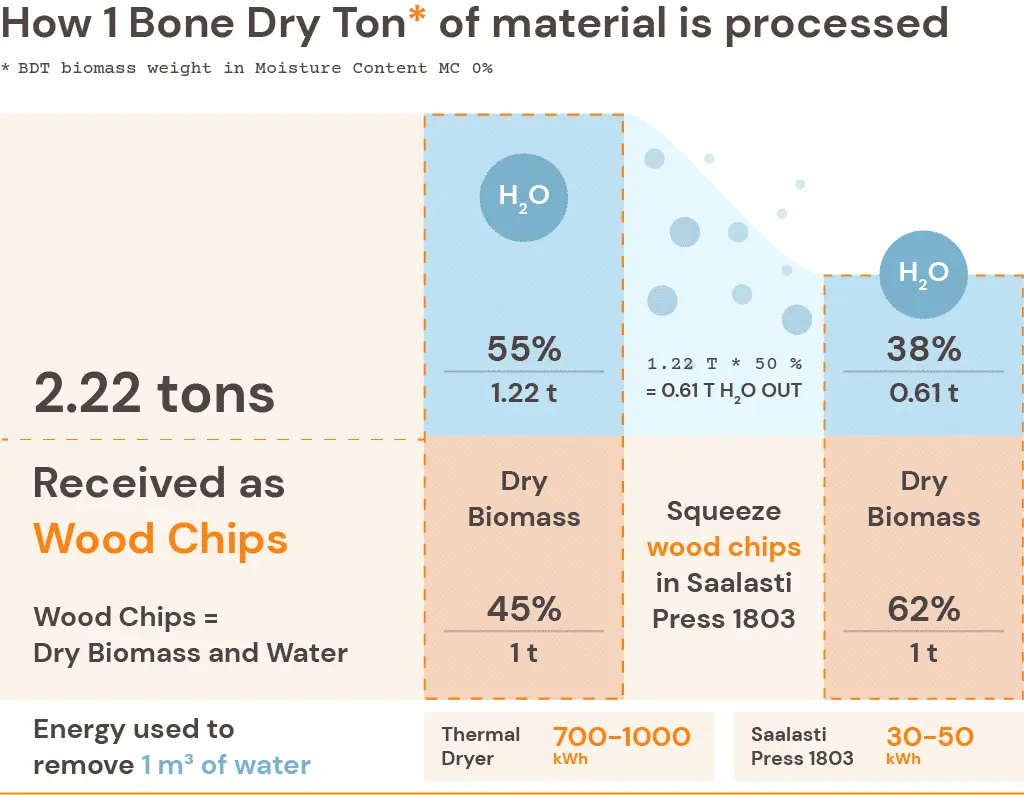

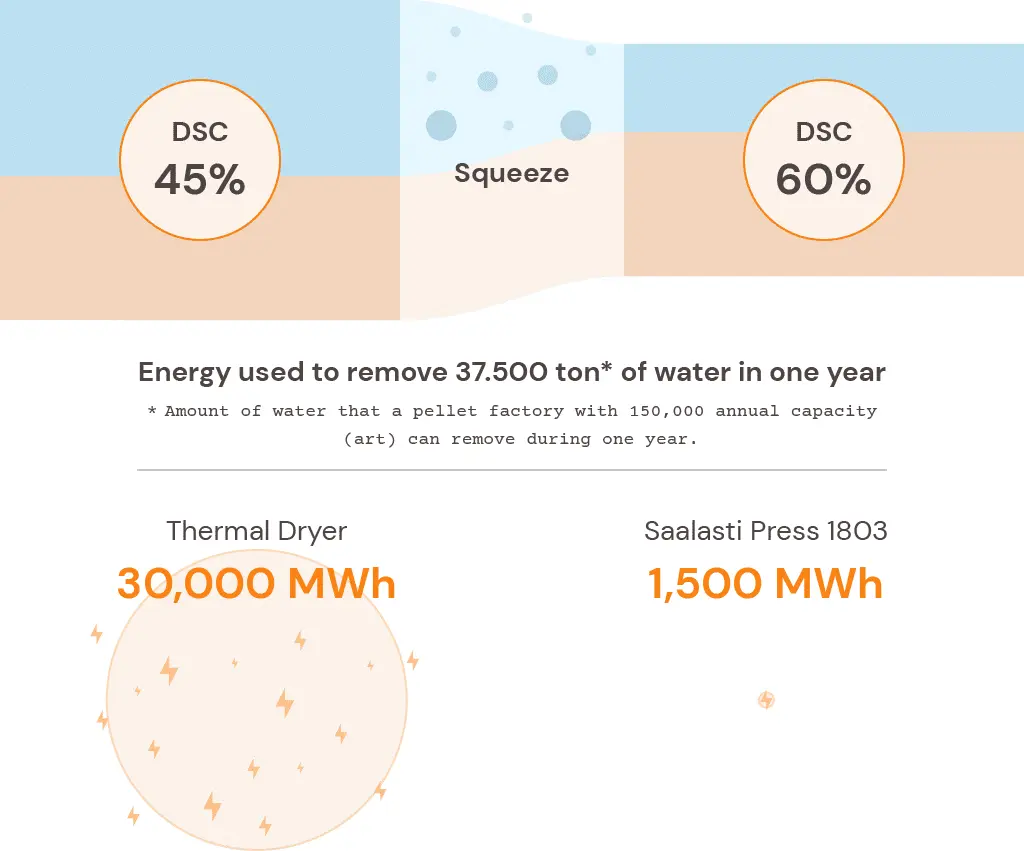

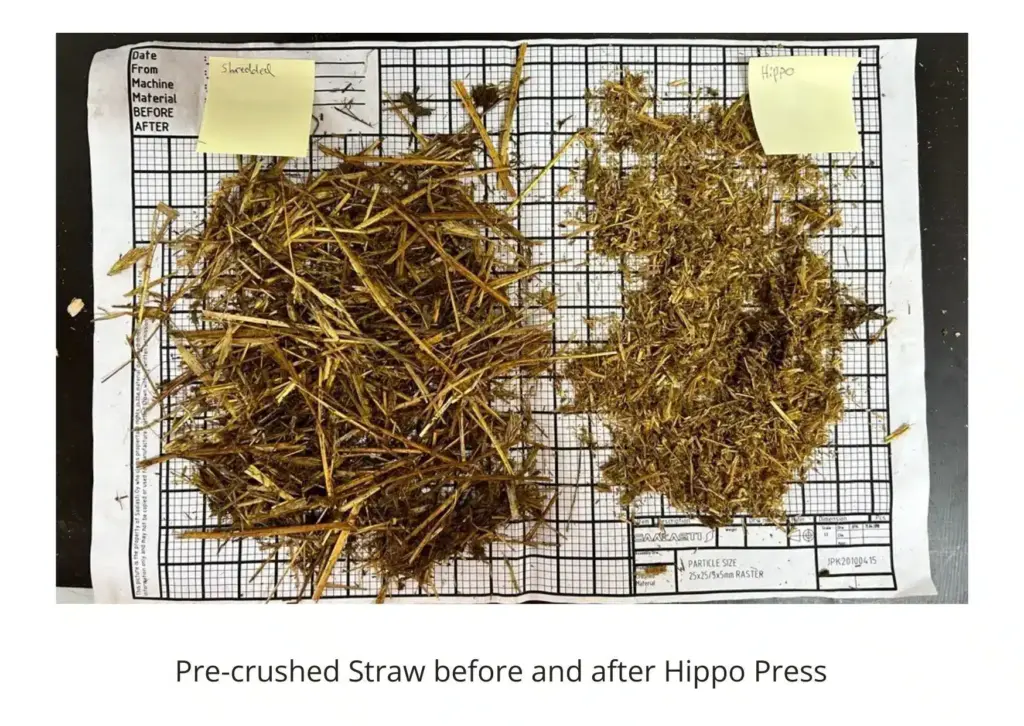

Saalasti High-Pressure Press 1803 is a new-generation press based on mechanical dewatering capability. Press dramatically reduces the moisture content of organic fiber-based biomasses such as wood chips and sawdust.

The press suits many industries where fiber-based biomass requires an energy-efficient drying method. For example, pellet plants, pulp and paper mills, power plants, and panel board operators can use the machine in their drying process.