News

Biomass testing: Validate your material, secure your investment

Are you curious about the potential of your fiber-rich biomass material? Do you want to enhance your industrial biomass processing capabilities?

The biomass test laboratory provides validated results before you invest. Discover how our testing facility helps you develop processes and reveal the hidden potential in new materials.

Our biomass testing facility is globally unique. We can test countless types of fibrous biomasses and discover new market potential.

Why test your biomass in a laboratory?

When processing large volumes of biomass, ensuring your process works before investing in a processing solution is crucial.

Will your material achieve the desired dryness? Can your agricultural residues be efficiently compressed? Can a new innovative material be processed into valuable output? The answers can be found through testing.

Our unique biomass test laboratory houses prototype-scale equipment that mirrors our industrial-scale machines. This allows you to test different materials and processes on a smaller scale before implementing them in full-size operations.

The advantages of biomass testing:

- You can verify the feasibility of your process with minimal risk.

- We can optimize the parameters specifically for your material.

- You receive documented performance data to support your investment decision.

This scientific approach to process validation has helped numerous industrial operations worldwide transform their biomass handling concepts into successful full-scale implementations.

Even seemingly similar materials, like pine from different geographical regions, can behave differently in processing. Pine from Nordic forests has distinctly different properties than North American pine, which affects its performance in industrial processes.

Testing your specific material under controlled conditions is crucial for your project’s success.

Through laboratory testing, you gain verified confirmation that your target performance values can be achieved. As a result, you can:

1) Validate materials and processes at prototype scale.

2) Minimize investment risks.

3) Optimize process parameters before full-scale implementation.

The test results establish guaranteed performance values that become part of your contract.

With decades of expertise in biomass, we demonstrate process performance at a prototype scale. Our biomass test laboratory shows precisely how your material will perform before you commit to full-scale equipment.

From wood bark to innovative materials, we can test it!

We can process practically any fiber-rich biomass in our test laboratory, which is one of its kind worldwide.

The most common materials we test are plant-based fiber materials:

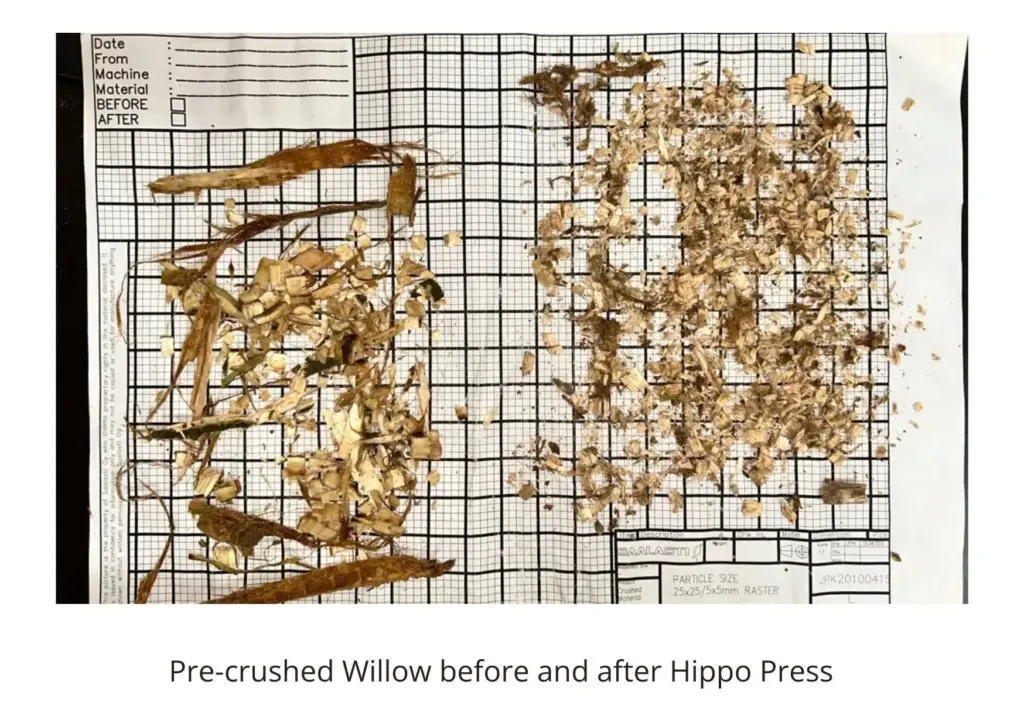

- Traditional wood-based materials (bark, chips, sawdust)

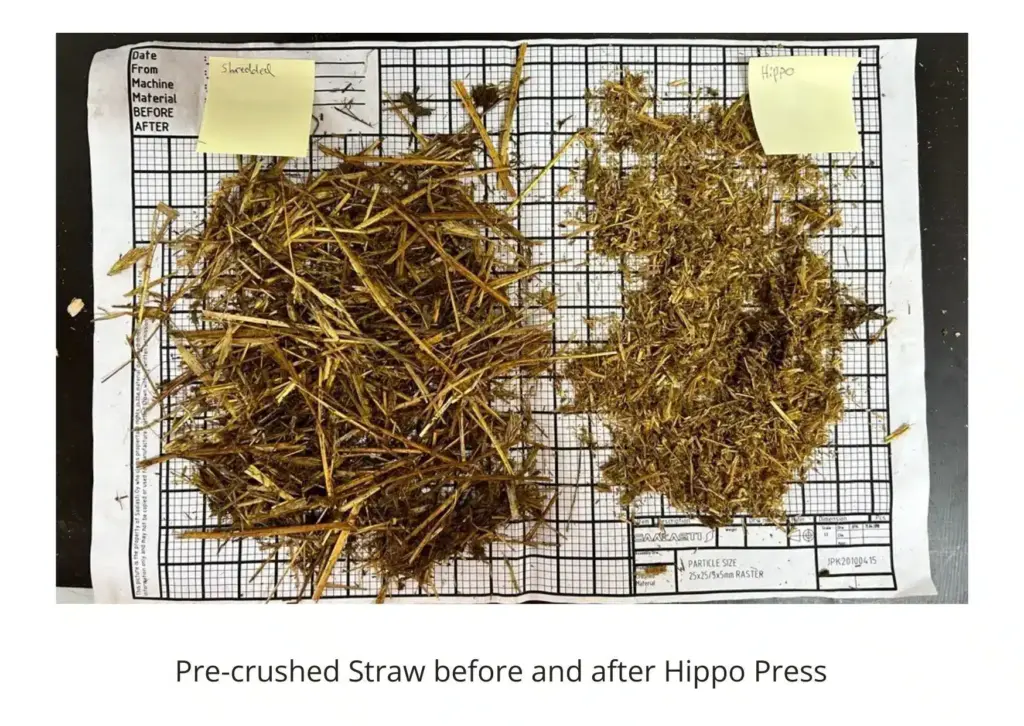

- Agricultural residues and straw

- Sugar cane

- Various types of organic waste

Additionally, we openly test other innovative materials, such as:

- Emerging fiber-rich materials, like textiles.

- Industrial by-products like brewery spent grain.

- Specialized plant materials, such as tomato stems.

If your material is not on the list, don’t worry, we can still figure out if it suits the process.

Turn your biomass concept into guaranteed performance

Our biomass test laboratory offers valuable data and insights for confident decision-making, whether you are developing new processes or optimizing existing ones.

We guide you from initial material assessment to detailed process validation, helping you understand the full potential of your biomass processing concept.

In our biomass test laboratory, we follow a proven methodology:

- Material characterization and analysis.

- Process testing at prototype scale.

- Performance optimization.

- Scale-up parameter definition.

- Guarantee value determination.

Each step in our laboratory testing process builds confidence in your investment decision while minimizing risks!

The process of testing your material in our biomass test laboratory follows clear steps:

- Send us a representative sample of your biomass material. Our experts will advise you on the required sample size and shipping instructions.

- Material handling. We follow necessary biosecurity protocols. This ensures we meet the requested safety standards while maintaining your material’s testing properties.

- Testing. We conduct comprehensive tests using our prototype-scale equipment, following the testing protocol for your specific needs. Our experts monitor and document every aspect of the process.

- Analysis and Results. You receive a detailed analysis of your material’s performance, including performance data process parameters scale-up recommendations documented test results that define guaranteed values for your contract.

Not to forget development opportunities! During testing, we may identify new potential applications for your material. In such cases, we can initiate a structured product development project together, following our Lean Service Creation methodology:

- IDEA – Exploring new possibilities

- VALIDATION – Confirming market potential

- PILOTING – Testing in real conditions

- GROWTH – Scaling successful solutions

This comprehensive approach ensures you not only validate your current process but also discover new business opportunities. Our laboratory specialists actively test different types of biomass worldwide, helping us develop sustainable solutions for various industrial needs.

Laboratory test results define guaranteed values for your contract.

Let’s test it!

Do you want to know how your biomass can perform to its full potential? It is possible in our unique laboratory!

Contact our biomass test laboratory team to discuss your specific material and requirements.