Many biomass processors use thermal evaporation as their default method for removing moisture. However, the moisture content of wood biomass can become an issue if your goal is to reduce energy usage and improve operational efficiency. The case for working with more dry mass is even greater when you consider the potential savings of pre-dried material.

Removing most of the water mechanically before applying heat makes the thermal dryer’s job easier and reduces the amount of energy needed. Furthermore, the dryer’s capacity increases when a significant amount of moisture is removed mechanically beforehand.

By combining a dewatering press with a dryer, biomass processors can reduce dryer energy demand, free up processing capacity, and work with a more stable feed.

Summary:

- Thermal evaporation is necessary in many biomass drying lines, but it doesn’t need to do all the work. Instead of relying solely on thermal evaporation, the best results are accomplished with a combination of a mechanical press and a dryer.

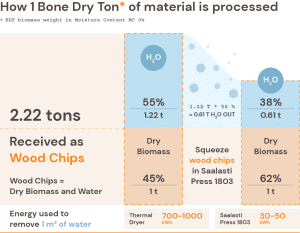

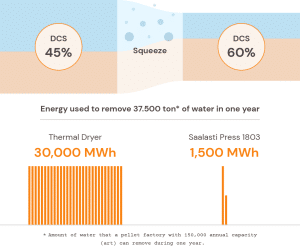

- Mechanical dewatering removes more than half of the water load and uses only 30–50 kWh per cubic meter of water removed, compared to 700–1000 kWh for thermal evaporation.

- By pressing first, you can cut dryer energy demand, free up dryer capacity and stabilize your downstream process, among other benefits. The press delivers biomass with consistent moisture content for year-round operation.

What is thermal evaporation, and how does it work?

In biomass drying, thermal evaporation means introducing heat into the particle. This causes moisture to evaporate, leading to a drier end product. The drying speed with this method is proportional to the amount of heat delivered and the temperature of the material.

Common thermal evaporation systems:

- Belt dryers: Biomass is carried between two mesh belts while hot air is blown through it from multiple points and layers.

- Rotary drum dryers: Material tumbles slowly in a rotating drum while hot air passes through, gradually evaporating moisture from the biomass.

Belt dryers are commonly used in biomass processing. However, removing water with only heat is energy-intensive and generates large volumes of VOCs (volatile organic compounds) and harmful blue haze.

Challenges of thermal-only drying and the case for mechanical presses

Integrating thermal evaporation with a mechanical press leads to the best results when you aim to extract more moisture from biomass, minimize energy use and maximize efficiency.

A mechanical press delivers biomass with consistent moisture content. This allows the thermal dryer to operate efficiently and use only a fraction of energy compared to relying solely on thermal dewatering.

Combining mechanical dewatering and thermal evaporation is where you see real efficiency gains:

- Less energy consumption → The more moisture you need to remove, the more heat and energy are required. For comparison, a thermal dryer requires 700-1000 kWh to remove 1m3 of water, whereas the Saalasti Press 1803 uses only 30-50 kWh.

- Lower gas emissions → Exhaust from belt and drum dryers results in VOCs, blue haze and high humidity. Regulations for VOC levels are tightening, and uncondensed exhaust released from thermal evaporation can exceed limits.

- Condensate handling → If the heat produced during thermal evaporation is recovered, condensate from exhaust needs to be treated appropriately.

- Process stability → Fluctuating input moisture means the dryer’s retention time and energy input must be constantly adjusted. Mechanical dewatering produces impressively stable and even output, which makes thermal evaporation easier after the fact.

Mechanical pressing is best suited for fiber-based biomass such as wood chips and sawdust. In pellet production, pressing the raw material before milling improves efficiency. The press delivers consistent moisture content, which means the thermal dryer uses less heat to remove the remaining water.

For soft bark and other fiber-based biomass, Saalasti offers a dedicated Saalasti Bark Press SP 1620.

How does mechanical dewatering work?

Unlike thermal evaporation, mechanical dewatering uses pressure, not heat, to remove water from biomass. In Saalasti’s high-pressure press, biomass passes between two surfaces under high pressure, which forces out loosely bound water from the material.

Key facts:

- Energy use: 30–50 kWh per cubic meter of water removed

- Moisture reduction: From 55–60% down to 38% water content

- Water removed mechanically: ~0.61 tonnes of water squeezed out per BDT of wood chips

- Energy source: Pure electric motor power with no thermal input required

- Material change: Pressing causes microcracks and fiber separation, increasing the effective surface area for later thermal evaporation.

Get to know Saalasti’s High-Pressure Press – Hippo 1803

Real-world impact: van Roje Pellet Plant

German pellet producer van Roje wanted to increase its pellet production capacity without investing in additional heat production or a bigger thermal dryer. However, the heating plant did not have enough heat to raise the volume of pellet production. Installing a Saalasti press before their belt dryer was the solution they were looking for.

By reducing water content mechanically with the Saalasti Press 1803, also known as ”Hippo”, van Roje achieved a higher production volume with the same amount of heat.

The results speak for themselves:

- Capacity increased from 60 to 90 tonnes per hour.

- No additional heat source or larger dryer required.

- Energy cost per tonne dropped significantly.

- Stable moisture removal makes year-round operation possible.

Read how van Roje transformed their wood pellet production

Mechanical + thermal dewatering: Optimize your drying line

Incorporating mechanical dewatering before thermal evaporation changes the whole drying equation.

For chipped biomass, fiber separation can significantly increase the effective surface area. This improves heat transfer, reduces the time needed to reduce moisture and removes more water with less energy. Furthermore, the output is more consistent once biomass is first processed in a mechanical press.

Example with green wood chips:

- Incoming biomass moisture: ~55–60% water (40–45% dry matter)

- After pressing: ~40% water (60% dry matter)

- Dryer load: Reduced by more than half

Mechanical vs thermal dewatering: Environmental and regulatory advantages

Both thermal evaporation and mechanical dewatering require water treatment after the biomass has been processed. However, mechanical effluent (pressate) is easier to handle than large gas streams, and its volume is smaller.

Furthermore, requirements for dewatering byproducts, like VOCs, are getting stricter. If exhaust gases are not condensed or filtered, this could create compliance issues.

| Thermal-only drying | Mechanical + Thermal |

|---|---|

| High exhaust volume with VOCs and blue haze | VOCs reduced by lower dryer load |

| Large condensate treatment needs | Smaller gas volume leads to smaller condensate volume |

| Risk of exceeding emission limits if uncondensed | Pressate requires treatment, but can be smaller in volume |

| High fuel use to produce heat | Lower thermal energy demand when biomass is processed first mechanically |

Why Saalasti

- Built for reliability → Saalasti machinery handles impurities and heavy-duty use without premature failure.

- 25+ year design life → Long-term ROI with proper maintenance.

- Repairable wear parts → Planned maintenance and original spare parts keep the machine operating.

- Tailored to your process → Testing biomass materials in Saalasti’s lab ensures optimal performance and compatibility.

Ready to optimize your drying line?

Let’s review your current setup and explore the efficiency gains of mechanical pre-treatment in your drying line.

¢

¢