Saalasti’s machinery is capable of processing a wide range of biomass materials to meet the specific needs of various industrial applications, such as:

- Roundwood and log processing

- Branches and debris processing

- Stumps and pre-crushed wood processing

- Bark processing

- Eucalyptus and hard species processing

- Mixed sawdust, small chips, and pellet feedstock processing

We supply both complete biomass treatment plants and individual machines for processing wood biomass. Our wide range of maintenance services, machinery upgrades, and high-quality OEM spare parts ensures reliable operation and performance for decades to come.

Saalasti machinery processes a wide range of wood biomass

Saalasti has been developing superior products for biomass processing since the 1980s to offer cost-effective, robust, and long-lasting machinery. Our biomass machinery includes chippers, cutters, crushers, and presses for the following applications and more:

1. Roundwood and log processing

Coniferous logs (pine, spruce, fir, larch) are typically used in power plants, biomass terminals, as well as pulp and paper mills. Saalasti Chipper H and Crush H allow precise size reduction for efficient combustion, drying. These machines support fuel preparation for biomass boilers and raw material processing in industrial wood handling lines.

Processing equipment:

- Saalasti Chipper H: A horizontal-feed biomass chipper capable of processing logs and other wood biomass into precise particle sizes.

- Saalasti Crush H: A horizontal-feed biomass crusher that handles wood-based biomass and makes it suitable for use in power plants and biomass terminals.

2. Branches and debris processing

Forest slash, like branches and tree tops, is often uneven and hard to process. Saalasti’s chippers and crushers convert this waste into consistent, fuel-grade biomass suitable for power production and heating. The ability to handle impurities and contaminants simplifies pre-cleaning from inorganic material.

Processing equipment:

- Saalasti Chipper H: Processes forest residues such as branches, tree tops, thinning residues, and loose forest slash with high-capacity chipping and adjustable particle sizes.

- Saalasti Crush H (horizontal feed models): Designed to crush various wood-based biomasses, including forest residues and slash, even when contaminated with sand or gravel.

3. Stumps and pre-crushed wood processing

Tree stumps contain large amounts of sand and soil, which can cause severe wear on ordinary chippers. Saalasti PreCrush can remove over 60% of inorganic matter before final crushing, which extends the service life of downstream equipment. Combined with integrated metal detection, PreCrush systems turn even dirty stump material into viable fuel for energy production.

Processing equipment:

- Saalasti Crush H: A horizontal-feed biomass crusher designed to withstand sandy stumps and other wood-based materials that cannot be handled with a standard chipper. Includes detectors for detecting and removing metallic contaminants from the processed biomass.

- Saalasti PreCrush: A specialized pre-crusher built for materials like unsliced stumps with sand and gravel. It can remove over 60% of inorganic material and includes metal detection for safe downstream processing.

4. Bark processing

Bark, often a by-product in saw and pulp mills, has high moisture content and inconsistent structure. Saalasti’s biomass crusher ensures effective size reduction, while the Saalasti Bark Press improves the combustion efficiency of biomass by reducing moisture. The result is cleaner-burning fuel for boilers or compressed feedstock for further processing.

Processing equipment:

- Saalasti Crush V: A vertical feed onsite crusher that reduces the particle size of wood and fiber-based biomass.

- Saalasti Bark Press: For bark dewatering and densification. Based on mechanical dewatering to remove excess water from bark biomass and enhance combustion efficiency.

5. Eucalyptus and hard species processing

Eucalyptus and other such hard-to-process materials are abrasive and difficult to cut cleanly. The Cutter V and its customized blades minimize “fluffy” bark that can clog conveyors and disrupt combustion. Saalasti Press units (e.g. 1615 M) enable effective moisture removal from these dry and fibrous materials.

Processing equipment:

- Saalasti Cutter V Series: Tailored to cut demanding biomasses such as eucalyptus and acacia bark, as well as several agro-biomasses,

- Saalasti Press (1615 M): 80 l-m3/h capacity for eucalyptus and other drier-than-average biomasses

6. Mixed sawdust, small chips, and pellet feedstock processing

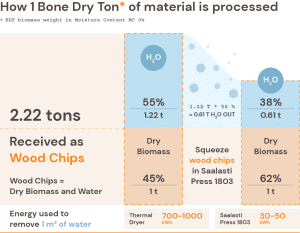

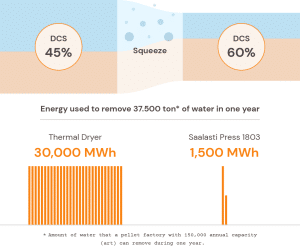

Fine residues from sawmills and woodrooms can be difficult to handle due to their moisture and particle size. Saalasti grinders mill these into uniform particles that are ideal for drying and pelletizing. The Hippo high-pressure press further enhances energy density and reduces drying energy needs.

Processing equipment:

- Grinder A and Grinder V: Designed for precision milling of fine biomass materials. Depending on the knife configuration, the grinders can produce fiber for pellets or fine wood particles suitable for insulation and bedding.

- High-Pressure Press – Hippo 1803: An advanced mechanical dewatering press that removes moisture from fine and fibre-based biomass materials like wood chips and sawdust.

Is your wood biomass missing?

The list above covers only some of the most common materials Saalasti machinery can process. Contact us if you are looking for machinery that can process materials other than the ones listed above. Our test lab is constantly looking for new materials Saalasti machinery can process.

Saalasti machinery for biomass processing

Saalasti machinery is engineered to process a diverse array of wood-based and fibrous biomass materials, accommodating both clean and impure feedstocks. Below is an overview of Saalasti machinery and the following materials each machine is capable of handling:

Saalasti Chipper H

The Saalasti Chipper H is a horizontal-feed biomass chipper designed for chipping and crushing various kinds of biomass. It is suitable for high-capacity facilities such as biomass terminals, power plants, and pellet factories.

Materials processed by the Saalasti Chipper H:

- Logs

- Branches

- Thinnings

- Tops of trees

- Exotic foliage

- Fossilized wood

- Rubber trees

- Oil palm biomass (trunks, fronds, EFB)

Saalasti Crush H

The Saalasti Crush H is a horizontal-feed biomass crusher designed for crushing all wood-based biomass, including impure materials. It is particularly suitable for high-capacity power plants and biomass terminals.

Materials processed by the Saalasti Crush H:

- Shortened and unshortened trunks

- Branches

- Forest residues

- Chopped tree stump material

- Waste wood

- Woody construction waste

Saalasti Crush V

The Saalasti Crush V is a vertical-feed stationary crusher designed for reducing the particle size of wood-based and other fibre-based biomass. It is suitable for sawmill debarking plants and power plants.

Materials processed by the Saalasti Crush V:

- Bark and other wood by-products from debarking plants

- Fiber-based biomass

- Wood waste

- Screening rejects

Saalasti Cutter V

The Saalasti Cutter V is a vertical feed industrial wood cutter for heavy-duty processing, specifically designed to cut demanding biomasses. It is suitable for processing bark from eucalyptus and acacia, among others.

Materials processed by the Saalasti Cutter V:

- Difficult-to-process materials, such as eucalyptus

- Acacia bark

- Screening rejects

- Trees and logs

- Wood waste

Saalasti Bark Press

The Saalasti Bark Press SP 1620 is a robust mechanical dewatering press designed specifically for bark and similar fibrous biomass. It significantly reduces moisture content to improve combustion efficiency, reduce transport costs, and prepare biomass for further processing. The Saalasti Bark Press is ideal for use in pulp mills, power plants, and debarking lines.

Materials processed by Saalasti Bark Press:

- Raw bark from debarking lines

- Mixed bark from different species

- Wet woodroom residues

- Eucalyptus bark

- Acacia bark

Saalasti High-Pressure Press HIPPO

The Saalasti HIPPO is a high-pressure mechanical dewatering press engineered to remove excess moisture from fine and fibre-based biomass materials. It is designed to improve the energy content of biomass used in boilers and pellet production, and to reduce drying costs. The Saalasti HIPPO press is suited for facilities dealing with fine feedstock at high volumes.

Materials processed by the Saalasti HIPPO press:

- Woodchips

- Sawdust

- Fine wood residues

- Fiber-based biomass

Why Saalasti?

1. Decades of biomass expertise: Saalasti has specialized in biomass processing machinery for over 75 years, serving industrial customers worldwide. Our long-standing expertise ensures that every machine is engineered with real-world durability, efficiency, and continuous operation in mind.

2. Versatility across biomass types: Saalasti machinery is designed to handle an exceptionally wide variety of materials, from clean conifer logs to abrasive eucalyptus bark and fine sawdust.

3. Proven reliability and longevity: Saalasti machinery is known for its decades-long service life. Many machines delivered decades ago are still running today.

4. Reliable support throughout the equipment lifecycle: Saalasti’s lifecycle services ensure continued performance and maximum value year after year. Our maintenance services, continuous upgrades, and OEM spare parts reduce production downtime and maximize the value of your biomass machinery.

5. Environmental and economic efficiency: Our electrically powered, stationary machines reduce emissions and fossil fuel dependence. They also slash the cost of energy production per MWh. Saalasti machinery helps you improve energy efficiency and produce more with less.

6. Customization and test-verified solutions: Our dedicated test lab can verify the processability of new or challenging biomass types before delivery. This ensures that our machines process specific biomass materials as needed.

Wood biomass processing machinery for your industry

Different industries rely on Saalasti machinery for processing wood-based biomass in demanding, large-scale operations. Saalasti’s robust equipment ensures efficient and reliable processing across diverse applications. Learn how our solutions serve the specific needs of each sector:

¢

¢